Description

Application

The system status of an electrically powered points can be with the

Point machine monitoring system “WB-PM” can be assessed. In combination with the

Data center “WB-PM DZ” is a systematic determination of physical as well as

made electrical sizes. Based on the data obtained, the

System status evaluated and a prediction, for example, with regard to wear and tear

be derived. This data enables you to carry out predictive maintenance

(predictive maintenance principle) and can thus avoid unforeseen failures.

In addition, maintenance plans can be made more evidence-based. The system delivers to you

detailed information without complicated installations and without approval-related information

changes. Retrofitting existing systems is therefore possible without any problems.

Description

The system consists of at least two components: the “WB-PM” and the “WB-PM DZ”.

If required, the system can be expanded with a SCADA system.

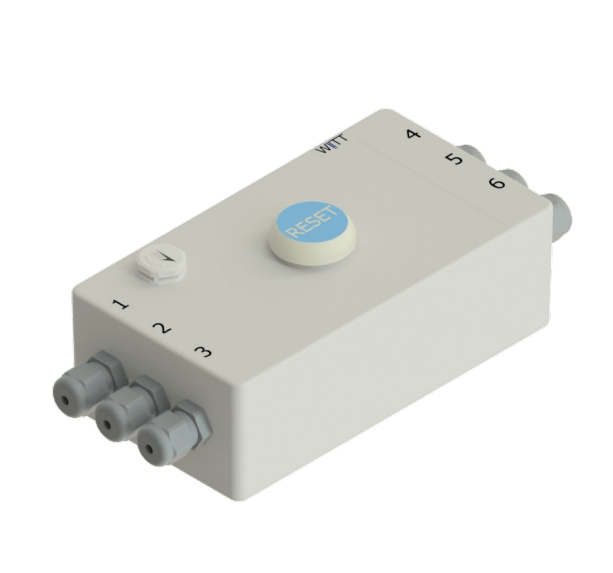

The WB-PM will be installed in the immediate area without changing the existing electronics

installed on the existing motor of the electric soft drive. It investigates constantly

measurement data of the connected units and evaluates them.

Measurement data is sent to the data center (WB-PM DZ) via cable or optionally “over the air”.

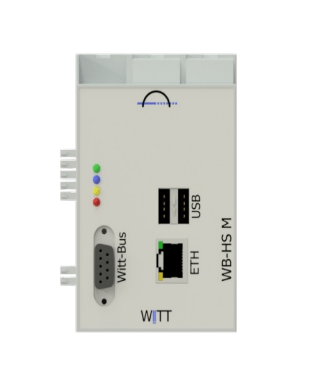

transfer. The measurement data from the WB-PM are collected here and sent to a SCADA system

transferred for long-term storage and further evaluation.

The intuitive user interface of the data center enables the user to easily

Configuration of the overall system. The user can see the current status of each

Query components in order to carry out work on the infrastructure or service work on site

support.

Integrating these components into your SCADA system is uncomplicated and can be done

carried out by WITT Solutions GmbH. The advantage of integration is that

that enables mass storage as well as the detection and evaluation of long-term cycles

will. It is possible to purchase a library for evaluating the engine condition.